Sierra Bullets: A Tradition of Precision

For over 70 years, Sierra Bullets has been dedicated to the manufacture of the most accurate bullets in the world. This commitment to performance has established a “Tradition of Precision” for which we’re known throughout the world.

Over the years, much has changed in the industry and in the marketplace. What hasn’t changed has been our focus on bullets. Hunting and target bullets for rifles and handguns are the only products we make, and we work hard to make them better than anyone else.

If you consider the large number of serious marksmen and hunters who use nothing but Sierra and their many accuracy records, we believe we accomplish our objective of a better bullet.

Since 1947

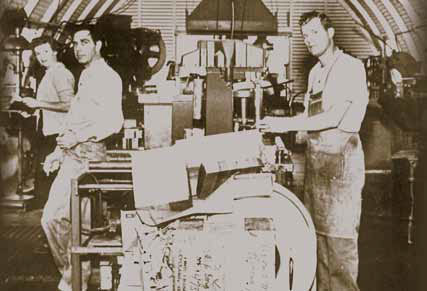

Sierra began in 1947 in a California Quonset hut building. At the time, World War II had just ended, shooting popularity was rising to unprecedented levels and the supply of high-quality ammunition was limited. Shooters were discovering that to satisfy their own demand, reloading was the answer. Frank Snow, Jim Spivey, and Loren Harbor recognized this and created Sierra Bullets to help fill the void. A few years later, an accomplished competitive shooter named Martin Hull joined Sierra. Martin brought with him an understanding of the market and the ability to translate ideas into a finished product. He was the manager of our ballistics laboratory for nearly 20 years. In 1969, Bob Hayden joined Sierra as Manager of Operations for The Leisure Group, who at the time was Sierra’s parent company. An engineer by trade and an avid hunter, Bob led Sierra through years of tremendous growth while greatly expanding Sierra’s product offering before his retirement in 2012.

In 1990, we left our factory in Santa Fe Springs, California for a new beginning in Sedalia, Missouri. Armed with years of experience in the manufacturing and testing of quality bullets, we designed and built one of the industry’s most advanced manufacturing facilities. While integrating the best of the old with the new, we enhanced our tool and die shop, upgraded our metallurgical laboratory and quality control systems, redesigned our process for washing and polishing bullets, and improved our bullet assembly equipment. Our shining star, however, was the construction of an underground, 300-meter test range, the longest privately owned underground bullet test facility in the world. Without it, we would not be able to conduct the degree of accuracy testing necessary for our stringent quality control requirements, nor would we be capable of producing the reloading manuals at the level we do.

Toll-Free Tech Line

Another significant addition to the Sierra arsenal was the development of our Bulletsmiths service and Toll-Free Tech Line. Every weekday, literally hundreds of marksmen call in and talk with one of our experienced ballistic technicians. Even if a caller is not using a Sierra bullet, our technicians are trained to have the answers to their questions about products, methods, and performance.

QUALITY MANUFACTURING PROCESS

Quality begins with the raw material. To ensure that only the most uniform materials are used, we check the grain size of the raw materials we buy with sophisticated metallurgical equipment.

If you ask someone what they demand most in a bullet, they will probably tell you “consistency in performance.” That’s why we’re dedicated to the highest level of precision in design, manufacturing, and quality control. And that’s what makes a Sierra bullet stand out from all the other bullets.

CADD PRECISION DESIGN

With today’s technology, design capabilities are mind-boggling. Since our move to Missouri, our tool and bullet design department has evolved from the traditional drawing board to a sophisticated computer aided drafting design system. This cutting-edge system and supporting software has greatly enhanced the design process and enabled us to take our bullet design to an entirely new level.

Our design process begins with talking to the people who use our bullets. Every year, we receive many requests for the addition of new bullets to our line. Although it would be economically impossible to produce every one, we do consider and analyze all the possible shooting situations for which a new bullet may be used. If we determine that there is a viable market, (as was the case in 1994 when we introduced seven new bullets), we select a design that will satisfy our three stringent bullet requirements.

Our three stringent bullet requirements

PRODUCING THE BULLET JACKET

All our bullet jackets are made from gilding metal, a copper alloy composed of 95% copper and 5% zinc. In order to match our different bullet requirements and meet stringent quality objectives, we buy nineteen different strip sizes of gilding metal and require three times more dimensional and quality control than is considered standard in the copper manufacturing industry. In fact, Olin Brass has a special alloy exclusive to Sierra Bullets. This enables us to build extremely high uniformity into every one of our finished bullets.

The bullet begins to take shape during the manufacturing process when the jacket material is first blanked and then brought through a series of drawing processes. Special tooling made in our own tool and die shop ensures that the jacket is drawn evenly and that uniform wall thickness is maintained for accuracy. Jackets which have been drawn to the proper wall construction are then trimmed to a length with a tolerance of +/- 0.001.” This ensures consistent weight and proper forming when the bullet is assembled.

After each step, the bullet jackets are washed and rinsed using a special cleaning process developed by our experienced personnel. During each phase of production, roving quality control inspectors check specifications to ensure that the only part to move on is a perfect one. Reports on the quality of parts being manufactured are maintained in every department and are periodically reviewed by shift supervisors.

PRODUCING THE CORES

While the jackets are being made, lead cores are being produced as well. We make the core of the bullet from four lead alloys: 6% antimony-4% tin, 6% antimony, 3% antimony, 1 1/2% antimony, and pure lead. For each bullet, we select the proper lead alloy for the best combination of accuracy and expansion in the finished projectile. A customized lead extrusion process contributes to our product uniformity.

Lead is purchased in billets, which are then individually extruded into spools of lead wire. These spools are stress-relief annealed to stabilize the material against further expansion, which might affect uniformity.

ASSEMBLING A SIERRA BULLET

Once the jackets and lead wire are brought together, they are fed into one of our custom progressive bullet presses. Strict controls are maintained so the lead core will produce a uniform weight for each bullet. Close inspections of the bullets during this process for visual and dimensional characteristics assure the uniform quality for which we are famous.

After the bullets have been formed in the bullet presses, they are tumbled in the front wash-and-polish operation to remove any surface blemishes and to polish the jackets. These finished bullets are then given a comprehensive visual inspection so only the best bullets will be packed for shipment to our distributors around the world.

QUALITY CONTROL

Our experienced engineering staff maintains strict quality control throughout the manufacturing process, including in-line sampling, inspection at each major bullet assembly step, stringent manufacturing tolerances, and accuracy firing tests.

Our underground testing range

In order to accomplish accuracy firing tests, we utilize our 300-meter underground testing range daily. A precision unrestricted machine rest conducts 200-yard accuracy evaluations on rifle bullets. We also conduct daily 50-yard accuracy evaluations on our pistol bullets using a specially designed machine rest. If a group of bullets does not meet our high expectations, the production run is rejected. This rarely happens due to the quality control procedures that go into the manufacturing process itself. However, accuracy firing tests are still important to ensure that every bullet we ship is one we can be proud of.

Once the production, inspection and testing process is complete, we pack the bullets into our custom green boxes, which have been designed to withstand the rigors of international shipping. They are then inventoried and put on their way to the millions of marksmen and hunters around the world.

Comments (0)